Tokyo, India, Jan 22: TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd., a leading global manufacturer of precious metal materials, will exhibit its Visi Fine Series, a lineup of highly radiopaque precious metal materials and other precious metal-based materials for medical device components, at MD&M West 2026, to be held February 3–5, 2026, at the Anaheim Convention Center in Anaheim, California.

First unveiled at the 2025 event, the Visi Fine portfolio harnesses TANAKA’s deep expertise in materials development and advanced processing technologies including diverse melting methods, ultra-fine wire manufacturing, and laser processing to transform precious metals into highly reliable materials for medical device components. The Visi Fine brand name is a coined term combining “Visi” and “Fine” It embodies the concept of delivering materials with excellent radiopacity, engineered through advanced processing technologies for use in highly reliable medical device components. By leveraging the high density, superior radiopacity, and strong resistance to oxidation and corrosion of precious metals such as gold and platinum, Visi Fine materials are particularly well suited for high-precision, minimally invasive medical devices.

“Minimally invasive surgeries and treatments have become a cornerstone of modern clinical practice,” said Yasutaka IHARA, Director & Corporate Officer, TANAKA.

“Smaller devices such as catheters, implantable products, and diagnostic and therapeutic systems require meticulous precision while remaining clearly visible under X-ray imaging to ensure effective care. Already utilized globally, the Visi Fine series delivers exceptional reliability, customization, biocompatibility, radiopacity, and corrosion resistance, supporting the development of next-generation, high-precision medical devices.”

To achieve these high standards, medical device manufacturers rely on premium materials from trusted suppliers. As the largest precious metals manufacturer in Asia, TANAKA combines regional leadership with a robust global presence, ensuring rapid support both domestically and internationally. With a 140-year history, TANAKA offers a comprehensive, end-to-end service model encompassing bullion procurement, materials processing and manufacturing, product sales, and recycling. This integrated approach enables medical device manufacturers to streamline supply chains, ensure material quality and traceability, and support sustainability initiatives through precious metal recovery and reuse.

Through its participation in MD&M West 2026, TANAKA reaffirms its commitment to supporting innovation in the medical and healthcare industries by supplying advanced precious metal materials backed by technical expertise, manufacturing excellence, and a resilient global supply network.

Main Exhibited Products

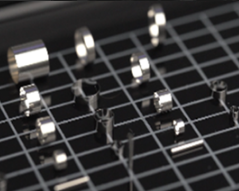

The main products on display at MD&M West will include precious metal materials and precision-processed components used in a wide range of medical device applications, particularly catheter-based and implantable devices that require high reliability, biocompatibility, corrosion resistance, and radiopacity.

TANAKA offers the Visi Fine series, a lineup of highly reliable platinum-based fine wire materials that deliver excellent radiopacity, corrosion resistance, and mechanical stability, making them well suited for medical device components such as marker bands, electrodes, and implantable parts. By leveraging advanced wire drawing and processing technologies, TANAKA provides fine wires with tight dimensional control and consistent quality, supporting demanding medical applications.

Marker Bands and EP Bands

Marker bands are essential components for enhancing visibility under X-ray imaging in catheter-based medical devices, supporting accurate device positioning during medical procedures. TANAKA manufactures marker bands from smooth-surface tubing, produced through the careful selection of high-purity materials and optimized manufacturing processes to ensure excellent uniformity, durability, and radiopacity.

Solid marker bands are available in a range of materials, including Pt PtIr10, and other precious metal alloys, designed to meet stringent medical device performance requirements. In addition, split marker bands are offered to provide greater design flexibility, enabling customized configurations tailored to specific device architectures and functional needs. All marker bands are manufactured under an ISO 13485–certified quality management system, ensuring consistent quality, reliability, and regulatory compliance.

Micromachining components

TANAKA offers precious metal micromachined components for medical device applications, including cardiovascular and peripheral vascular treatments. By leveraging advanced processing technologies, such as precision machining, femtosecond laser processing, stamping, and welding, TANAKA produces complex-shaped components with excellent burr control and clean surface finishes. A broad range of precious metal materials including Pt, Pt-Ir, Pt-Ni, and Pt-W alloys supports high-precision designs that meet the stringent performance and reliability requirements of medical devices.

Rhodium sheets are specifically designed for mammography filter applications. With a controlled thickness of 0.05 mm, these rhodium sheets feature a smooth, crack-free surface and excellent thickness uniformity. By leveraging its expertise in high-purity precious metal refining and advanced materials processing, TANAKA delivers rhodium sheets with the quality and consistency required for reliable performance in mammography imaging systems.